Call us

Free Support: +62821-2525-3939

Available: In stock

Construction | Installation | Sales & Services

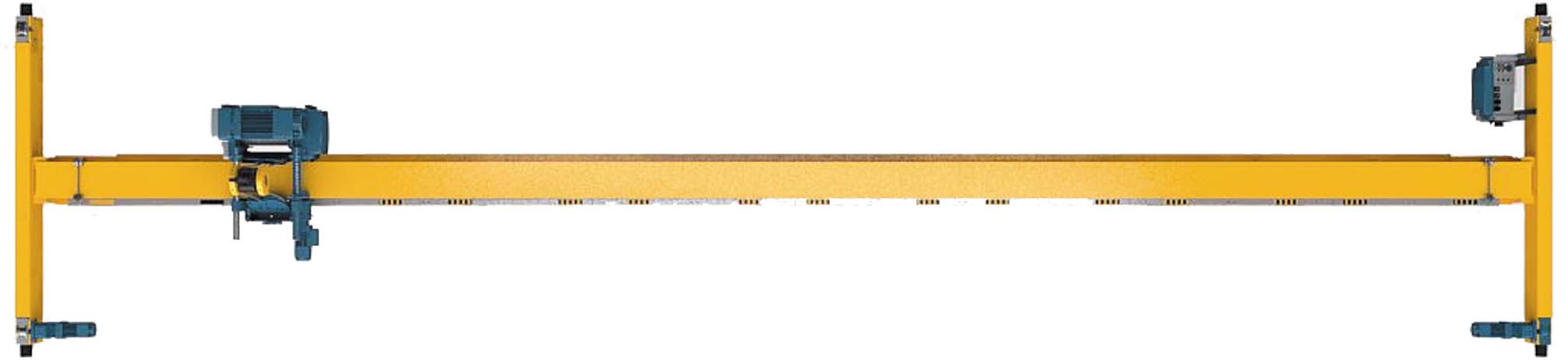

Variable configurations offer even greater flexibility for planning and load handling.

Compact design and minimum trolley approach dimensions boost crane performance.

The energy chain on the V-type crane provides a protected power supply along the entire length of the crane girder without any visible cable run along the crane.

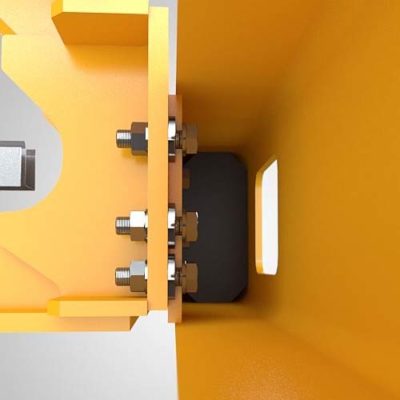

The newly developed diaphragm joints reduce resonance frequency by 30% by effectively accommodating pressure and tensile forces.

Parallel alignment of the connecting surfaces provides for minimum wear of travel wheels and crane runways.

The V-type crane is available with our state-of-the-art DRC radio remote control.

Parallel alignment of the connecting surfaces provides for minimum wear of travel wheels and crane runways.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Utenim ad minim veniam, quis nost rud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Utenim ad minim veniam, quis nost.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Utenim ad minim veniam, quis nost rud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Utenim ad minim veniam, quis nost.

Free shipping on all order

30 days for free return

Support 24 hours a day